Select the product options and the quantity and then click the “Request A Quote” button. If you do not see the option you want, note that on the request form. You may include your lighting fixtures list and attach files.

We will contact you with any questions and strive to provide you with a competitive quote as quickly as possible.

NOTE: This can not be used with LuxR large flanges.

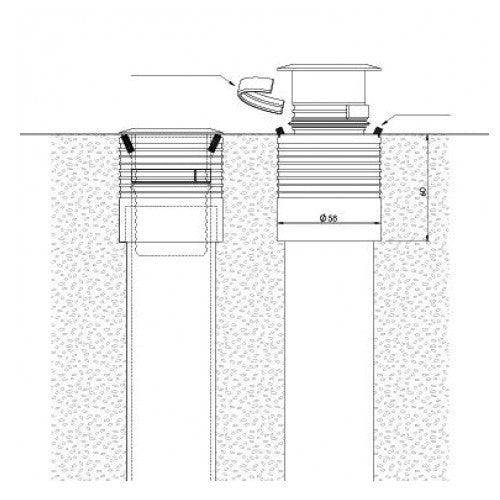

The Security Canister can be either cast into concrete directly, or chemset with a suitable concrete epoxy or urethane caulk into a prepared hole. Using a 58mm or 2 1/4" core drill, a neat hole can be accurately cut in the concrete and you can be assured that it will be perpendicular to the surface.

Route the wiring out of the hole and thread through the canister bore. Set the canister in place and allow to cure fully. Connect wiring to the luminaire.

Insert the two set screws and give them a few turns each only. Leave the hex key positioned in one of the screws for now....Insert the two collets around the luminaire body above the conduit seal. Press the luminaire and its conduit seal into the security canister until the flange rests against the hex key. The collets will now be retained deep inside the canister. Tighten both set screws until they stop, then back off each screw half a turn. Press home.

Click for Accessory LuxR M2 M4 Security Canister Spec Sheet V1.pdf ![]()

We deliver worldwide

Your shipping service or ours

Project quotes

Competitive project quotations

Top-notch support

Personal expert service

Secure payments

The latest payment technologies

NOTE: This can not be used with LuxR large flanges.

The Security Canister can be either cast into concrete directly, or chemset with a suitable concrete epoxy or urethane caulk into a prepared hole. Using a 58mm or 2 1/4" core drill, a neat hole can be accurately cut in the concrete and you can be assured that it will be perpendicular to the surface.

Route the wiring out of the hole and thread through the canister bore. Set the canister in place and allow to cure fully. Connect wiring to the luminaire.

Insert the two set screws and give them a few turns each only. Leave the hex key positioned in one of the screws for now....Insert the two collets around the luminaire body above the conduit seal. Press the luminaire and its conduit seal into the security canister until the flange rests against the hex key. The collets will now be retained deep inside the canister. Tighten both set screws until they stop, then back off each screw half a turn. Press home.

LuxR™ products are manufactured from the highest quality materials and are designed to provide many years of reliable service when correctly installed. Our modular construction ensures that all components, including the LED Board and Internal Driver, can be easily disassembled for maintenance. Our confidence in the quality of our products is demonstrated by the comprehensive warranty that comes with all LuxR luminaires.

LuxR™ stainless steel* and copper luminaires have a 10 year replacement warranty on body components, subject to the standard conditions listed below (*excludes underwater fixtures ).

All LuxR™ aluminium luminaires with a UV stable powder-coat finish and underwater fixtures have a 5 year replacement warranty on body components, subject to the standard conditions listed below. We do not suggest powder-coated fixtures be installed where they can be walked or driven over as this can damage powder-coated finishes.

All glass lenses supplied with LuxR™ luminaires have a lifetime warranty.

5 year warranty on other LuxR™ components, LuxR™ accessories and are subject to the standard conditions listed below.

Coverage on plug-in (drop-in) LED lamps, power supplies and other 3rd-party components are limited to the manufacturer’s warranty.

• incorrect voltage

• failure to follow the installation instructions supplied with the product

• improper or incomplete installation or assembly

• installation by an unqualified and/or unregistered electrician

• improper or unauthorised electrical connection

• corrosion due to electrolytic reactions caused by the presence of electrical current in the ground or water

• inadequate maintenance procedures

• high pressure washing

• external causes, such as, but not limited to, fire, extreme temperature, water, flood, moisture, dampness, liquid touching or entering the product, other foreign material entering the product, dirt, dust, rust, corrosive conditions (including salt and sand), theft, vandalism, collision, infestation by pests or insects, electrical surges or dips, hail, thunderstorms, lightning strikes, high voltage spikes or incorrect polarity connection, earthquakes, tornadoes, acid rain, acts of God, terrorism, war, environmental conditions or any other act or circumstance beyond our control.